Vents

Once the structure was satisfactory the outter layer of poly was added and attached using 2in plastic strapping (at the top and bottom of the pony wall) and roofing nails. At that point three vents were added. One at the top and two at the bottom each 1/3 from the door.

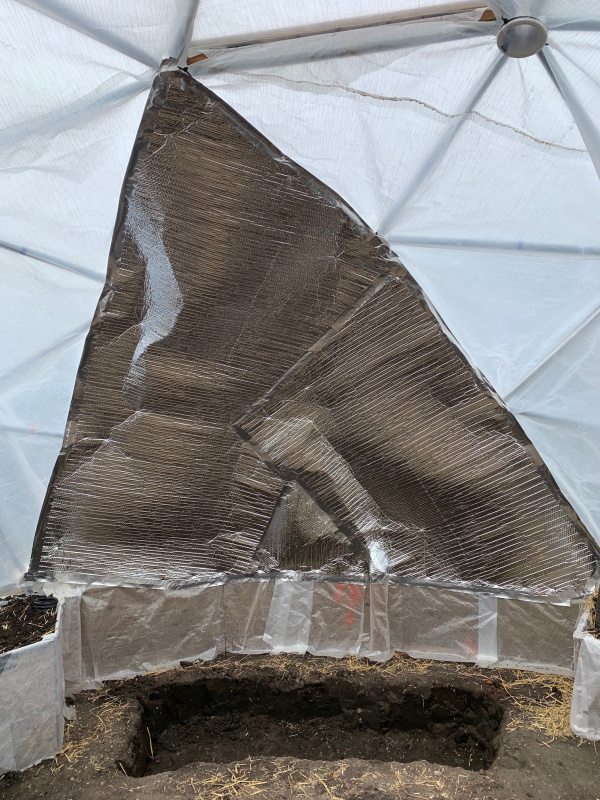

Treated lumber was cut to size and mounted to the outside of each strut with screws where each vent would be. The poly was carefully cut from center to each strut (hub not strut). The excess poly was then rolled and stapled to the lumber. Oversized cardboard was used to create a tough (rough) template. Final measurements were done on the template and it was cut to fit on top of the previously installed lumber.

When happy with the fit the template was used to create a wood frame of the vent. A cross piece was added to each frame for strength and to provide a mount for the Baylis vent openers.

These could have been better but we aren’t carpenters and they work for us.

Note: screening for pests is worth considering. Also our door was a great buy at $20 but is (it) has no screen. A screen door would be much preferred to assist circulation. I leave the current door open but that could lead to mice, birds or other pest issues at some point.

Mice are unlikely to be able to climb the poly to the vents with the door closed. Below grade 6in of hardware cloth was installed to reduce mouse access in the cooler seasons.

I forgot. The gap between inner and outer poly at the corner of each vent was sealed with spray foam. Wasn’t sure if it would hold with air movement etc but it seems to be ok and providing a seal. There is also a small gap remaining where the vents seat onto their frame of the greenhouse. Weather stripping may be added here however lack of light in the fall is a bigger issue than keeping heat in. Rain runs in here from the top as well which could impair the tape holding.